Below is an update from bespoke gearbox genius, Chris Weismann of Traction Products Los Angeles.

This communication reflects the complexities of the many projects being undertaken in a seemingly impossible timeframe.

Hey Reg,

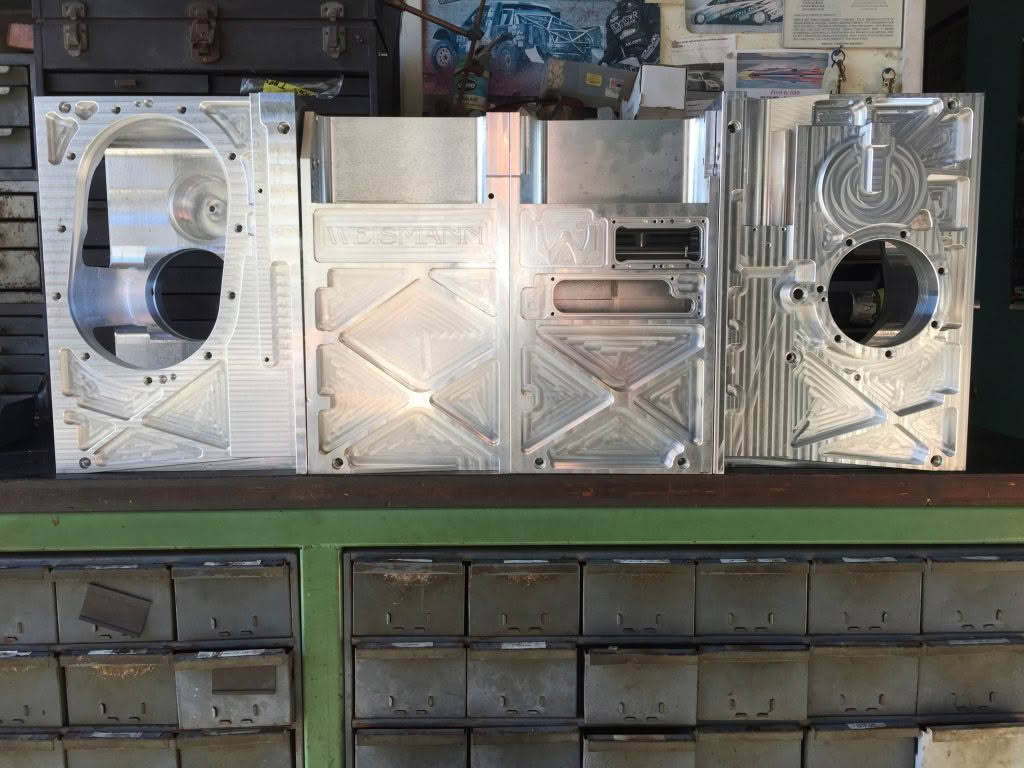

I worked through the weekend to get the 6th op done on the 4 cases. I had a few battles yesterday that pushed my patience, but I got around them and I was able to finish the 4th case.

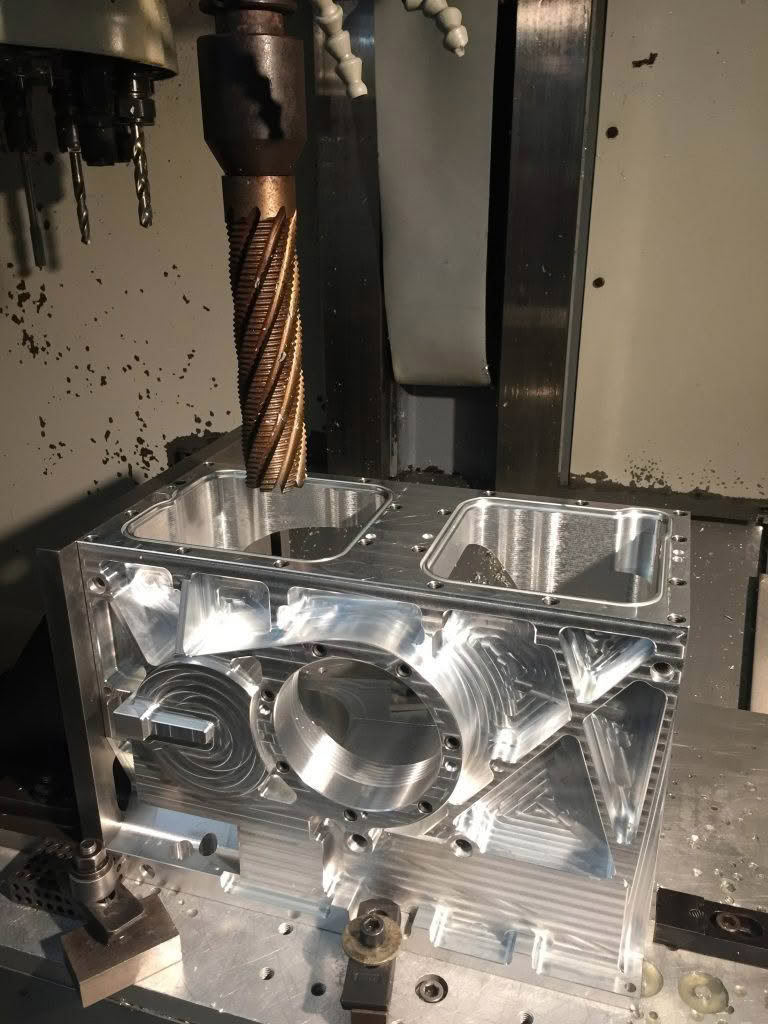

Today I have been machining the long drill holes for the oiling system, from the top and bottom. I can barely machine them while the case is on the bed. The holes are done, and I am set up and machining the clearance for the bevel pinion with “Big Bertha”. I told Jesus to leave that for me to do later. You can see the tool I have to use to do it. It takes a while, but I can reach all the places I need to machine with it.

As I was looking over the 3D drawing and comparing it to the machine cases I noticed one hole is not machined completely, from the first op, so after I am done with the bevel clearance, I will machine that hole deeper, it is the access hole from the air valve manifold to 5th and 6th gear.

I have 11 more inserts to put in, I have already hand tapped the holes to depth. 238 inserts, I hope I never have to install another…

I have a couple of oil mist drill holes to drill by hand, and then I think I can put some bearing in it and start doing an assembly. I got the majority of the bearings and seals in, so I have been getting parts together to do some sub assemblies.

Later,

Chris